We go over the pros and cons of this new tech

Home 3D printers have now been on the market for many years and are affordable to anyone who wants one. They’ve grown from a hobbyist curiosity to useful tools that can help you fix small problems around the home, create art pieces or help you prototype parts for projects. The uses for a 3D printer are only limited by your imagination!

Now, however, an entirely different type of 3D printer is entering the home market. These “resin” 3D printers use very different principles to create 3D objects compared to the ones you may have seen thus far. What is a 3D resin printer and should you buy one over the more traditional models already out there?

A Recap of Conventional 3D Printers

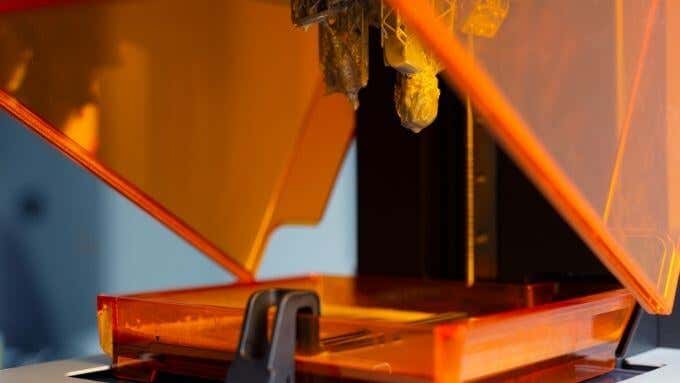

What most people think of as a “3D printer” is actually something called an FDM (fused deposition modelling) printer. It runs a filament of material (usually plastic) through a hot extruder head and then deposits precise layers of the material to slowly build up the model.

The most common FDM machine is the “Cartesian” type of 3D printer. This has a print head mounted on movable rails that can put the tip of the head precisely at any XYZ coordinate within the build volume of the printer.

Whatever type of FDM printer you’re looking at, it’s the layered extrusion of filament material that’s shared among them all. Resin printers are fundamentally different in this regard.

Resin 3D Printers Explained

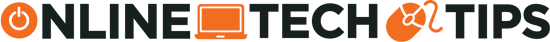

Resin 3D printers differ in a few fundamental ways from FDM printers. First, the material is a liquid resin rather than a spool of filament. This liquid is kept in a reservoir.

The resin printer still uses a build platform for the model that’s being printed, but it’s usually upside down. The platform is lifted out of the resin vat as each layer is formed. The resin itself is light-sensitive and cures when exposed to the right type of light.

A precision light source is used to form each layer on top of the previous one until the entire finished model has been pulled from the vat. It certainly looks much more futuristic than FDM printing!

Types of Resin Printer: SLA, DLP & LCD Technology

While all resin printers use the basic principle of curing photosensitive resin with a light source, they don’t all do it in the same way. There are in fact three major subtypes of 3D resin printers.

SLA: Stereolithography

The Solidmaker Laser 3D Printer

SLA is actually the original 3D printing technology and has a long history in engineering, especially in aerospace.

This type of printer uses a laser and movable mirrors to direct a small point of light. Wherever the ultraviolet laser is focused will harden the resin, so each layer can be rapidly drawn.

SLA printers can have the upside-down inverted design, where the model looks like it is pulled up out of the tank, but they can also have an upright design where the platform is lowered into the tank of resin as each layer is completed.

SLA printers generally produce very smooth surfaces and offer high-precision detailed prints.

DLP: Digital Light Processing

The Spintray Moonray DLP Printer

You may have heard the term “DLP” in relation to projector technology before and that is indeed the connection here. DLP resin printers use the same digital micromirror technology that DLP projectors use to project images.

In this case, the DLP projection is used to cure an entire layer of resin at a time, which makes DLP printers a little faster than SLA models, which only cure one point at a time.

DLP resin printers are also known for nice smooth surfaces, but large print areas might not show the same sharp and accurate detail as laser-based SLA machines.

LCD: Liquid Crystal Display Resin Printers

The PHROZEN Sonic Mini UV Photocuring LCD Resin 3D Printer

These printers use a monochrome LCD panel with a UV backlight to cure each layer. The LCD panel essentially acts as a mask by selectively blocking out light or letting it pass. This is a clever use of mature and well-understood LCD technology and has driven the cost of resin printers down dramatically. Most of the affordable resin printers that you can buy today use LCD technology.

LCD resin printers are faster than SLA machines and more accurate than DLP printers, which can exhibit distortion. The downside of LCD printers is that they have a shorter lifespan than the aforementioned technologies and they need more maintenance.

The Pros and Cons of Resin Printers

So why should you (or should you not) buy a resin printer over the more conventional FDM machines?

On the positive side of the equation:

- Resin printers offer much more detailed and smooth models.

- Resin prints don’t require extensive post-print finishing to look good.

- They are faster than FDM machines.

- Resin models are generally stronger and more resilient.

On the negative side of the equation:

- Resin printing is more expensive overall.

- It’s messier and requires more maintenance.

- You need to prepare a safe environment to print in and store your resin.

- Resin printers have smaller build volumes on average.

- Uncured resin is toxic and has to be handled with significant care.

It’s important that any prospective resin printer owner be entirely prepared for the reality of resin printing, the dangers, environmental issues and maintenance burden. Take the time to watch a few YouTube videos to see the printing process from start to finish.

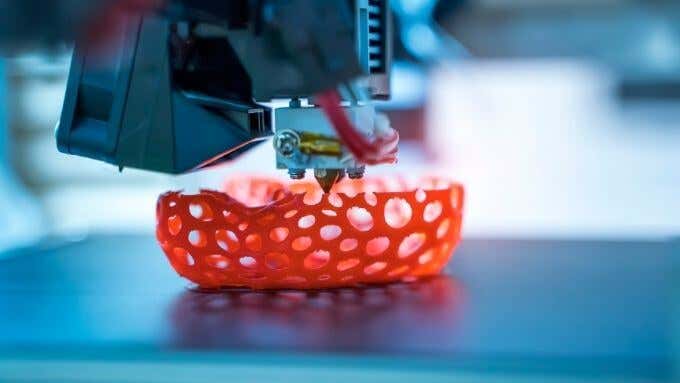

Who Should Buy a Resin Printer?

The main market for desktop resin printers is people who need to make small, finely detailed models. For example, if you want to create detailed pieces for tabletop gaming or intricate 3D jewelry, a resin printer might be a good option. If you are a 3D sculptor using software such as Zbrush, only a resin printer is going to do your finely detailed models any justice.

It is entirely possible to paint resin models, although you need to follow a lengthy process of preparing the resin surface to hold paint. If you don’t need the detail and quality of resin prints, then you’re far better off opting for an FDM 3D printer. You can also improve your FDM print finish quality by using techniques such as sanding, for a smoother model surface.

3D Resin Printer Recommendations

There are more and more resin printer choices on the market as time goes by, but one or two options stand out.

First, there’s the Elegoo Mars 2, which is a UV resin LCD printer with a 2K resolution. It has a fast-curing system, and uses an LCD panel with a longer lifespan than usual. It also has several measures in place to make resin printing safer and less messy, such as a disposable resin vat and silicone seals to curb unwanted smells and leakage. With over 2500 reviews and a 4.5-star average on Amazon, it seems like a great entry-level choice for the money.

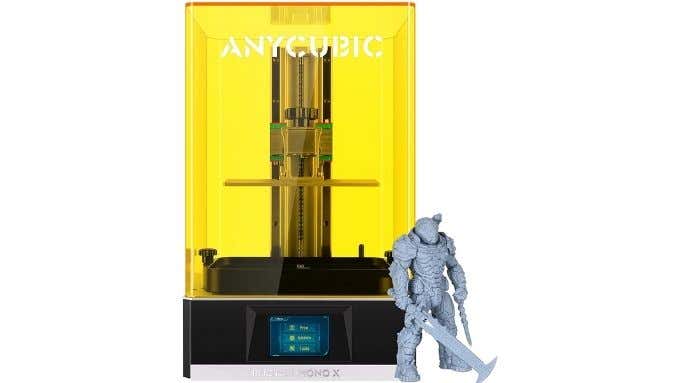

The AnyCubic Photon Mono X also caught our eye as a much more high-end (and costly) option. The substantially higher asking price nets you a larger, higher-resolution LCD panel and an impressive build volume, at least as far as resin printers go.

Of course, you should do your own research according to your specific needs, but based on customer reviews and their specifications, these two printers are a great place to start.